GBM Works and Deltares test a silent method for installing offshore wind turbine foundations

Start-up GBM Works B.V. tested a new concept for a quieter installation of monopiles (foundations of offshore wind turbine) in the Geotechnical laboratory of Deltares. The tests provided sufficient insights for the scaling up of the method for demonstration testing at the Maasvlakte 2 test location. This took part in Phase 1 of the SIMPLE project.

Wind turbines and their foundations have increased enormously in size in recent years and they are expected to get even bigger. As a result, there is also more impact on marine life. With the project ‘Silent Installation of MonoPiLEs‘ (SIMPLE), GBM Works wants to work with Deltares to demonstrate that their this new installation method is fast and efficient. Installation costs are expected to be reduced because sound-mitigation measures that are often required can be scaled down and the time window for installation can be extended.

Combination of techniques requires research

The GBM Works method uses water-injection technique to liquify the soil, in combination with vibration at the pile tip using a vibro-drill. Neither technique is new as such, however, the combination and the use for monopiles is and requires research before possible application.

Model tests in a controlled environment provide an understanding of the process

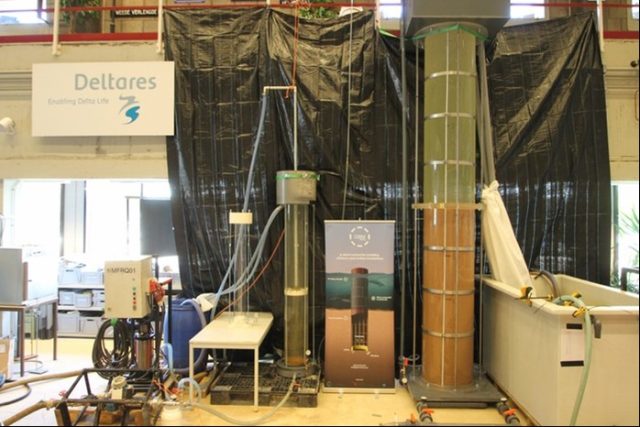

The new method was modelled and tested in a controlled environment in the Deltares Geotechnical laboratory. In a Perspex tube 4.2 m long and with a diameter of 0.6 m, experiments were conducted with different combinations of sand densities, grain-size, layering and with varying flow rates in order to learn more about the process. The process was monitored in different ways. The test set-up was built in close collaboration with GMB Works and the tests were run by their team, together with Deltares experts, to experiment with the different variables.

Ben Arntz, the founder and director of GBM Works: “For us as a start-up, it is very important to do this together with Deltares, a renowned research institute in the offshore world. It creates confidence for the industry. In their geotechnical laboratory, we tested our vibri-drill method for monopile installation.” These tests were carried out with support from the Top Sector Energy and Netherlands Enterprise Agency.

With the results from the tests, GBM Works could optimise the method and perform a demonstration at the Maasvlakte 2, which was successfully concluded September 2020.