Lock Facility

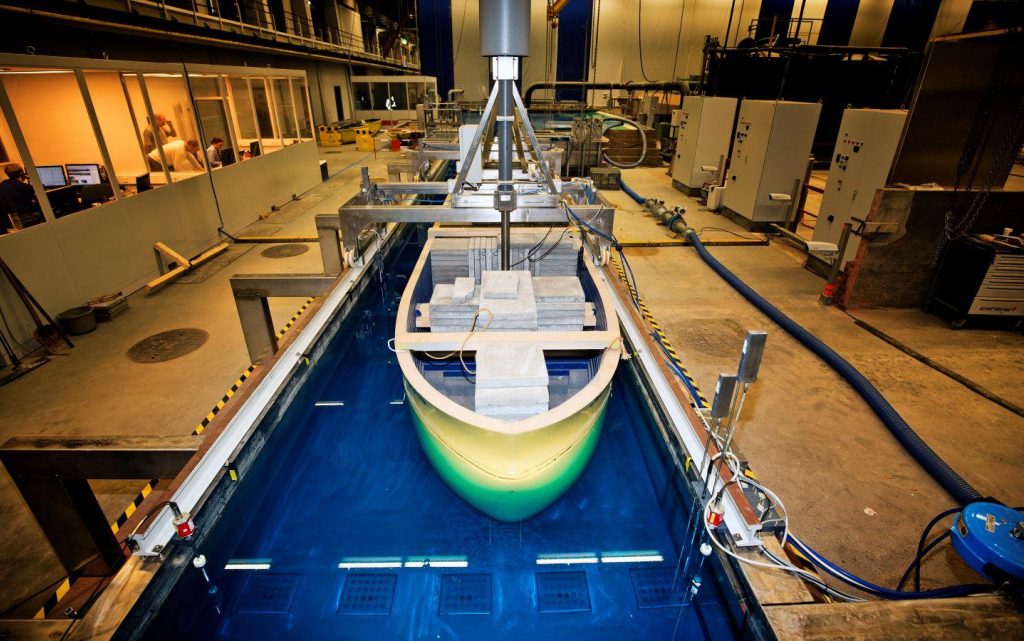

Smooth and safe passage through a lock is a priority for shipping worldwide. As the economy grows, water transport increasingly relies on ever larger vessels. However, many locks built in the last century no longer meet current standards. Consequently, they are either being replaced or renovated. Two main factors contribute to this: the aging of existing structures and foreseen changes on climate conditions, types of use and regulatory requirements. Deltares has a state-of-the-art lock facility that can be used to test the design of new locks, contributing to safer and more efficient waterway navigation worldwide.

Ensuring safe and efficient passage through locks requires a well-designed and effective levelling system. The Deltares Lock Facility can be used to test various levelling system designs, including assessing the forces exerted on vessels within the lock chamber. We also investigate the impact of density currents in sea locks. Understanding these currents is essential for safe and smooth operations. Deltares combines data from scale model tests with results obtained from computer models. This integrated approach enables a comprehensive comparison of various levelling systems and their optimisation.

Areas of application

Large vessels navigating through locks require a smooth and safe passage. Achieving this involves optimising the filling and emptying operations of the chamber to minimise delays for shipping while ensuring forces within the limits on the moored vessels. Various levelling systems and scenarios can be tested at the lock facility. In these tests we measure the resulting hydrodynamic forces acting on the vessel during the levelling process. Additionally, we can also measure the flow velocities near the bottom to provide input for the design of bottom protection measures, to protect against possible scour. These results can be used to optimise the levelling system and the levelling process.

In parallel with physical scale models, Deltares develops computer models to simulate specific lock processes. Lockfill models the forces exerted on vessels during the levelling process and Wanda-locks (both 1D mathematics models) simulates water exchanges caused by density flows. Detailed three-dimensional flow calculations (CFD) further contribute to the understanding of flow dynamics. The results obtained with the physical scale model are used to validate the numerical models with the aim of establishing a well-calibrated modelling toolbox that can be used to evaluate different hydraulic conditions.

Projects

The conceptual design for the levelling system in the new IJmuiden sea lock laid the foundations for the Deltares Lock Facility in 2014. Typical studies in the Lock Facility relate to:

- Navigation locks: determining the achievable levelling times and acceptable flow velocities. Different levelling systems have been tested such as openings in the lock gates, short lateral culverts and long longitudinal culverts with bottom grids on the lock floor (e.g. New Sea Lock in IJmuiden, New Lock in Terneuzen);

- Salt intrusion: study of the flow patterns around the salt screen used to selectively withdraw salt water near the new lock in IJmuiden.

Technical specifications

The facility has a lock section and two adjacent approaches with a total area of approximately 60 m x 20 m. In addition to standard instrumentation for measuring discharges, water levels, forces and densities, advanced measurement techniques such as PIV (Particle Image Velocimetry) and PTV (Particle Tracking Velocimetry) can also be used to obtain detailed flow fields.

- Size of facility: 60 m x 20 m

- Maximum water depth: 0.70 m

- Scale between 1:40 and 1:30

- Measurement of water level, density, pressure, discharge, flow velocity, temperature

- Measurement of forces on the vessel in three directions

- Cameras for flow visualisation (top view, side view)

- Advanced measuring techniques (PIV, PTV) for detailed flow patterns

- Brine storage and salt mixing tanks

- Underground reservoirs for storage of salt water and freshwater

- Maximum pumping capacity: 400 l/s

- Different types of vessel e.g. bulk carriers, container vessels

- Data acquisition system and steering software for the scale model

You have not yet indicated whether you want to accept or reject cookies. This means that this element cannot be displayed.

Or go directly to: