Lockfill

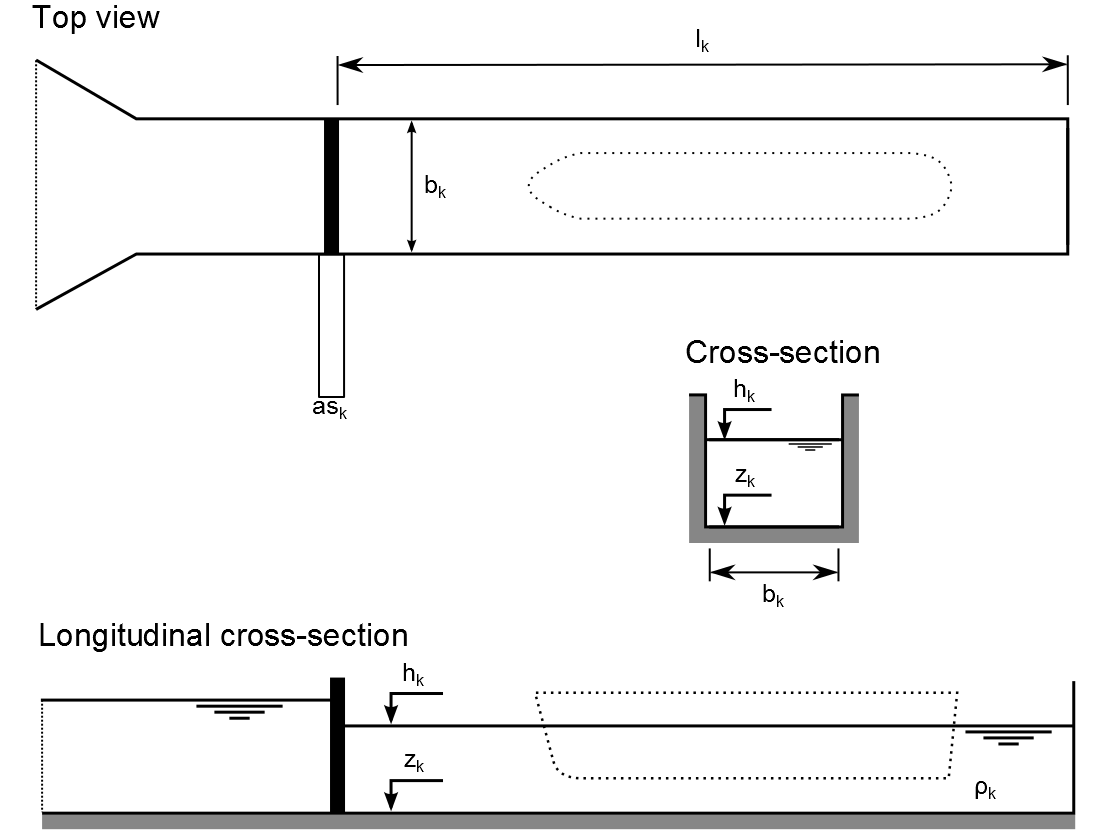

LOCKFILL is a quick tool developed by Deltares, enabling the assessment of a shipping lock’s performance, in terms of levelling times, forces on vessels and flow velocities on the approach harbour bed.

In order to limit the delay for navigation it is of importance that the operation of a navigation lock progresses smoothly and within a minimum of time. Therefore, it is desired that the process of filling - and emptying of the lock chamber is executed at the highest possible pace.

However, lock operation must also be safe from the shipping point of view; this requires that the hydraulic forces on the ships in the lock chamber, and in particular the longitudinal forces, remain acceptable during operation and that the rise or drop of the water level in the lock chamber occurs at a moderate rate.

Because the latter demands are directly related to the layout of the filling - and emptying system and the way this system is operated, a carefully designed system is required.

The quick tool LOCKFILL enables the assessment of a shipping lock's performance. This simulation software product computes the longitudinal forces on the ship which are caused by translatory waves, momentum variation, skin friction, the filling jet and a water density difference, based on a one-dimensional approach.

The program allows the calculation of various filling and emptying systems in the heads of the lock, e.g. openings in the lock gates, pipes through the gates fitted with butterfly valves, lifting gates or short culverts in the lock head walls.

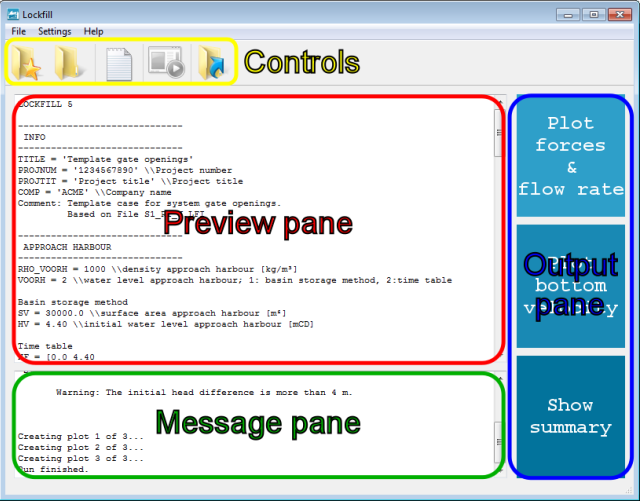

The software has a graphical user interface allowing easy input manipulation and showing the computation results in graphs and key indicators. Alternatively, the program can be run in command line. LOCKFILL is available free of charge.