Unique and first in the world 3D modelling to forecast thermal discharges in the Tennessee River

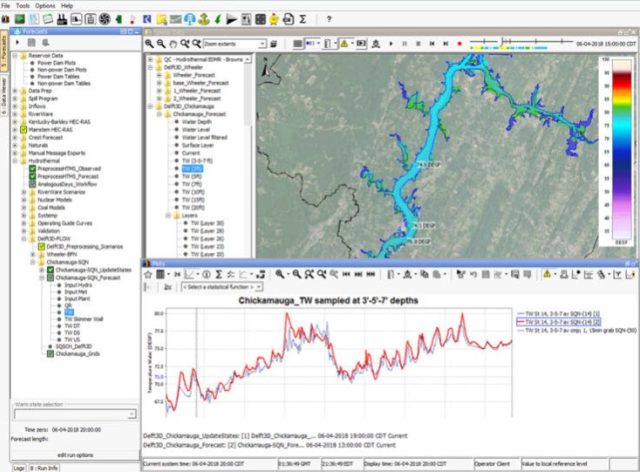

With the latest hydrothermal Delft3D model implemented in Delft-FEWS, Deltares successfully developed operational 3D forecasting models for the Tennessee Valley Authority (TVA). These operational models support TVA in protecting the local ecology and optimising the operational performance of multiple power plants along the Tennessee River.

Cooling water and minimum environmental impact

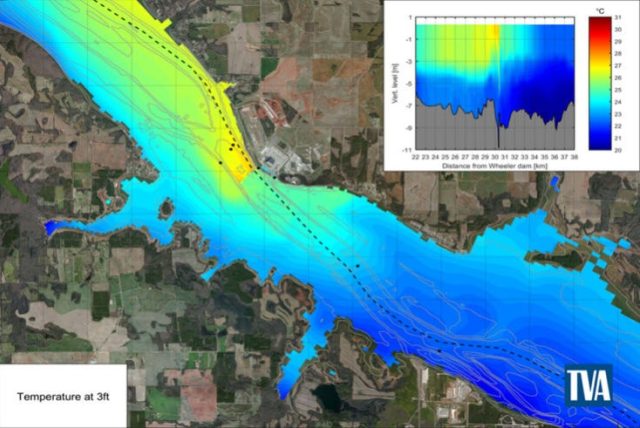

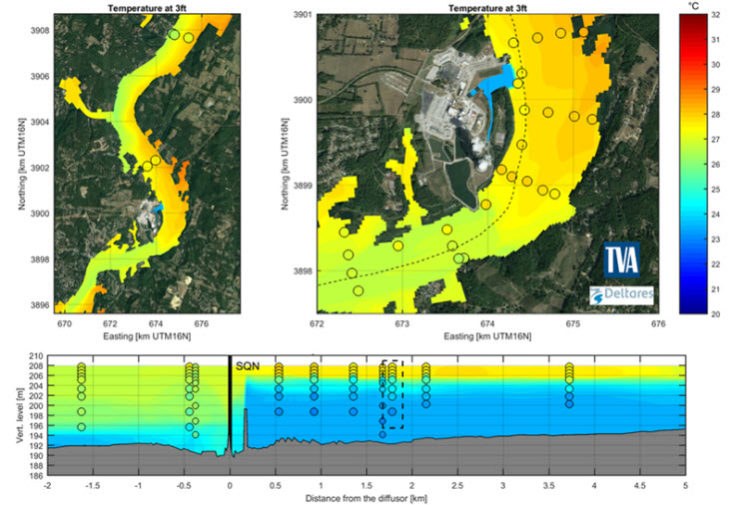

Along the Tennessee River, TVA operates multiple hydro dams and nuclear power plants. The power plants use Tennessee River water for cooling purposes. After passing the heat exchangers in the plant, the heated cooling water is discharged back into the Tennessee River through submerged diffusers, to mix the heated water efficiently with the river water. To ensure that the environmental impact is kept to a minimum, the downstream temperatures are continuously monitored and checked against environmental compliance criteria and reported to the state. When downstream temperatures are expected to reach the compliance threshold value, economically less favorable mitigating measures such as using cooling towers or releasing additional reservoir water to increase the river discharge are triggered by TVA.

Forecasting river water temperatures made possible

To support TVA in their operational decision making, Deltares and Deltares USA jointly expanded an existing Delft-FEWS system to incorporate Delft3D models to forecast the Tennessee River water temperatures and simulate the impact of potential mitigating measures on downstream water temperatures.

The Tennessee River is a complex system of a series of reservoirs separated by TVA’s hydropower dams

Hydrodynamic expert Roland Vlijm

Hydrodynamics, meteorology and human interventions all impact the temperature of the Tennessee River water. During summer, the Tennessee River stratifies with warm water near the surface and cold water from upstream reservoirs near the bottom. To accurately simulate the Tennessee River temperature including all relevant processes in one integral system, we developed a generic coupling routine, i.e. COSUMO. This routine couples TVA’s own plant model and detailed discharge model to a large scale hydrothermal Delft3D model. This allows for a dedicated and time efficient modelling assessment that takes into account each process.

To prove the validity of the 3Dmodels, TVA invested in dedicated field campaigns to collect data under critical operational circumstances at low flow. Deltares expert Rob Uittenbogaard who designed, and on the spot supervised the field work: “It was fascinating to see operators manipulating dam releases to create sloshing events in large reservoirs for the purpose of measuring velocity and temperature profiles around the plant”.

Forecasting is live

After extensive validation of the models with this field data the system was ready to go live. Now TVA is able, within half an hour, to accurately predict downstream water temperatures in the Tennessee River two days ahead. If temperatures are projected to reach a critical threshold, this forecast system provides TVA sufficient lead time to react appropriately in order to preserve environmental quality.

In addition, in the process of the model development, valuable lessons were learned on the natural Tennessee River system and how to monitor this efficiently on a daily basis.

Based on these insights new measurements stations have been installed that provide additional relevant information that is directly fed into the Delft-FEWS system

Ben Balk, Deltares USA

The next coming years Deltares will continue to work closely with TVA to evaluate the operational performance of the forecasting system and to further tailor the forecasting system to the needs of TVA.

Project Manager Pascal Boderie is proud of what has already been accomplished so far: “This system is unique and up to my knowledge the first in the world in the field of operational 3D reservoir modelling. With this project going towards its completion, I am proud that with the use of our dedicated software and the expertise of our experts we successfully provided a fit-for-purpose solution that financially benefits TVA and protects local ecology at the same time.”