D-Geo Pipeline - Horizontal Directional Drilling

D-Geo Pipeline enables the fast design of a pipeline configuration, installed using the Horizontal Directional Drilling (HDD) technique.

In Horizontal Directional Drilling three installation stages are considered: Pilot drilling; reaming the initial pilot borehole and pulling back the pipeline. The initial borehole is called a pilot hole. The diameter of this pilot hole is enlarged using a reamer. Depending on the required final borehole diameter, the borehole can be enlarged in several steps using reamers of increasing diameters. Finally, the pipeline is pulled into the borehole.

Features of Horizontal Directional Drilling

- Advanced input of the ground water pressure distribution.

- Drained and undrained behaviour of soil layers.

- Graphical output of calculated drilling fluid pressures.

- Library with steel and polyethylene pipelines.

- Standard calculation scheme for bundled pipelines.

- Calculation of settlement of the soil layers below the pipeline.

- Standard pipe stress analysis.

Drilling fluid pressures

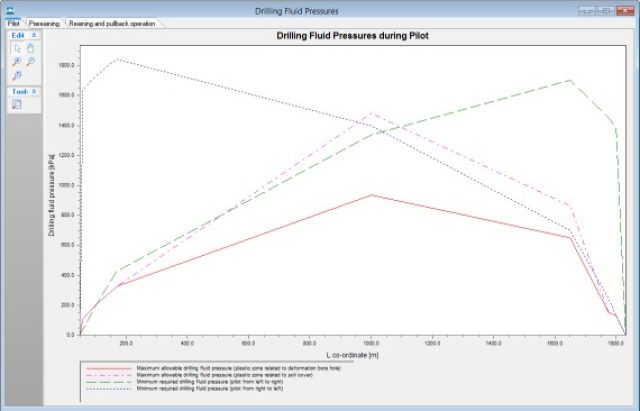

The minimal required drilling fluid pressure is the pressure necessary for an effective return flow, capable of transporting cut soil particles towards the surface. The upper boundary of the allowable drilling fluid pressure indicates the pressure at which a blow-out is likely to occur. The lower boundary indicates the pressure at which fractures around the borehole are expected. Both minimum and maximum allowable drilling fluid pressure depend on depth and soil properties.

Drilling fluid pressures are calculated along the entire borehole and visualised in a graph showing both the upper and lower boundary. Drilling fluid pressures are calculated for all installation stages (pilot, reaming and pull back).

Pipeline material

D-Geo Pipeline Horizontal Directional Drilling is capable of dealing with pipelines made of different materials. For steel and polyethylene a database containing the material data is available. The database enables a quick re-calculation for alternative material types and dimensions.

Pull back force calculation

D-Geo Pipeline Horizontal Directional Drilling calculates the pulling force on the pipeline that is required to pull the pipeline into the prereamed borehole. The pull back force is based on buoyancy control and consideration of the soil-pipeline interaction in the bends of the drilling line.

Pipeline stress analysis

Soil mechanical parameters are used for a pipeline stress analysis. The standard pipeline stress analysis by D–Geo Pipeline Horizontal Directional Drilling is based on a limited set of parameters. D-Geo Pipeline Horizontal Directional Drilling calculates the stresses in the pipeline during the installation stages in both axial and tangential direction. In a comprehensive report a stress verification is given for each pipeline material used. The calculated stresses are compared with the allowable stresses according the Dutch pipeline code (NEN 3650).

The pipeline stress report contains:

- used input data

- calculated axial, tangential and combined stresses for all installation stages

- verification of the pipe stresses

- check on pipeline deflection

- check on implosion for polyethylene pipelines.

The Horizontal Directional Drilling module is available as part of the D-Geo Pipeline HDD package. For more information, see the D-Geo Pipeline Service packages.