Deltares Geotechnical Laboratory

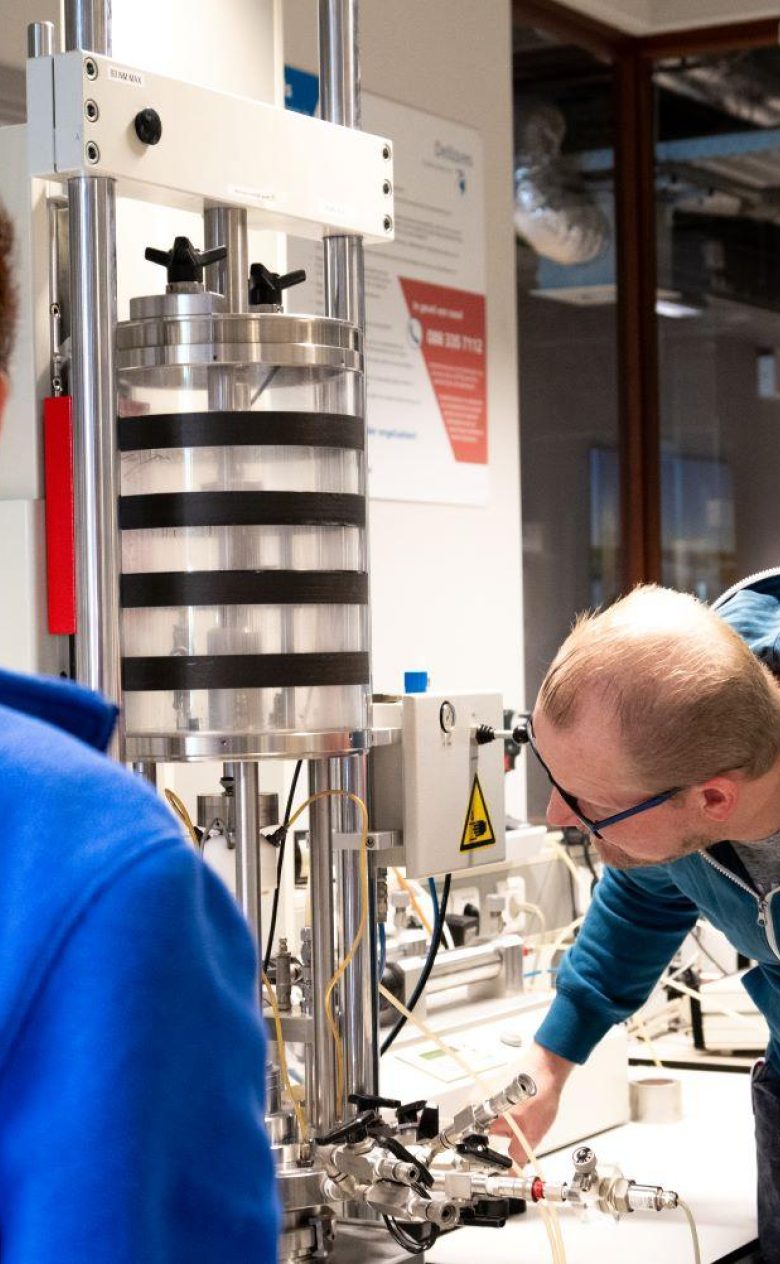

The Deltares Geotechnical Laboratory (DGL) specialises in the development and execution of advanced non-standardised experiments on various types of soil. These experiments aim to determine soil parameters under specific conditions, as well as to investigate the physical behaviour of soil depending on various conditions.

In doing so, our data not only serves as a crucial bridge between field studies and computer models, it also contributes to the applied research on soil behaviour. Additionally, the validation of computer models based on the results of laboratory research is becoming an increasingly important objective of the experiments.

In anticipation of future challenges and changing conditions, such as those caused by climate change, our laboratory research supports Deltares’ mission to provide innovative solutions tailored to the evolving needs of society.

You have not yet indicated whether you want to accept or reject cookies. This means that this element cannot be displayed.

Or go directly to:

Examples of the capabilities we offer

- Classification (description, grain distribution, organic content, water content, density, emin & emax, etc.)

- Direct (simple) shear, both static and cyclic

- Triaxial tests, both static and cyclic

- Bender element testing

- Oedometer, CRS & K0-CRS

- Permeability tests (constant & falling head)

- Pressure plate extractor

- HyProp

- Rotary erosion (designed to analyse the erosion of soil)

Examples of specialised testing possibilities

- Large scale tests: LDSS, large triaxial apparatus, large oedometer

- Temperature controlled triaxial tests

- Unsaturated triaxial test

Much of our laboratory equipment can be deployed in a flexible manner. For instance, we can equip most devices with (load) sensors with various ranges, from highly sensitive with small range, to less sensitive with a larger range. Another example is the addition of local strain sensors to our triaxial devices to measure deformations directly on the sample, or the use of bender elements for research on the dynamic behavior of soil.

For almost all of the experiments, the data is processed using in-house made custom software programs which are linked to a database, ensuring the integrity of data and its processing. For modifications of experiments, the development of new tests, or special requests from clients, we can adjust the existing software or develop new software as needed.

Practical applications

The practical applications of our research are vast and impactful. Following are some examples of our areas of expertise and related projects that have been undertaken in our laboratory.

Soil structure interaction

Soil element tests provide for numerical modelling and simulation of soil-structure interaction for predicting the performance of structures under various loading and environmental conditions. Projects undertaken by the Deltares laboratory include:

- The performance of tests on cohesive materials below railway tracks for assessing the effect of increased and heavier rail traffic on the stability of railway embankments

- By expanding our knowledge of the interaction between soil and underground structures, pipes and cables can make optimal use of the available space underground. To investigate this interaction, direct shear tests are carried out where the soil moves over the coating of the pipes. Based on these results, the surface of the pipes and cables can be optimised to improve the interaction between soil and structure.

Offshore wind

Offshore structures, such as wind turbines, rely on foundations for structural integrity. Understanding and characterising the soil structure interaction is key in optimising foundation design in terms of costs, time, and performance. Advanced soil element testing provides essential information to characterise the ground properties e.g., stiffness and dynamic response. The Deltares laboratory offers a wide range of advanced laboratory testing capabilities to establish these crucial soil properties. Deltares supported various offshore wind projects with its advanced testing capabilities.

Recent examples are:

- Cyclic soil testing and construction of cyclic contour diagrams for numerical modelling and cyclic monopile – clay interaction: Monopile Improved Design through Advanced cyclic Soil modelling in clay (MIDASclay)

- Characterisation of engineering properties of offshore soils and assessment of soil parameters for drivability analysis: Silent Installation of MonoPiLEs III (SIMPLE III)

- Sand behaviour under different loading conditions, stress paths and density states for calibration of constitutive model for assessing cyclic behaviour of monopiles in sand: Monopile Improved Design through Advanced cyclic Soil modelling (MIDAS)

- Steel plate-soil interface tests to back-calculate the tensile response observed in field pile load tests: Tubular Pile Pull-out Testing Program II (TPPT-II) (grow-offshorewind.nl/project/tppt2)

- Testing of glauconitic sands to characterise material behaviour for offshore pile driveability analysis.

Dykes & flood defenses

Stability of dykes is significantly affected by the response of the groundwater in relation to the water body in front of the dyke. As climate change progresses, fluctuating conditions of extreme dry and wet cycles are becoming increasingly common. This has consequences for the groundwater in the subsurface. Therefore, there are several developments currently in progress to be able to research this effect.

One development is researching the effect of soil suction on the strength of unsaturated soils, conducted using a specially adapted triaxial apparatus. Within dykes, there is a zone in which the level of saturation, and consequently, suction varies. In this zone, the drained shear strength depends on those parameters, which therefore also fluctuates considerably. From a certain threshold value in the degree of saturation, the soil behaves as if undrained.

Shear strengths

Heavily consolidated materials are commonly used for the construction of dykes, often consisting of silty and sandy clays. In conventional undrained triaxial compression tests, this material shows a very high undrained shear strength. This led to the question whether these shear strengths will be activated during a potential slope instability of a dyke. For this reason, we designed a series of non-standard triaxial tests that follow a variety of different stress paths during undrained shearing, involving different combinations of horizontal and vertical stresses applied to the samples. The results indicate that during undrained shearing, the shear strength is independent of the applied stress path, but the pore water response is different.

Locally sourced soil for dyke improvement

Due to its favourable impact on CO2 emissions, interest in the use of locally sourced soil for dyke improvement is increasing. This research has determined, amongst other things, that the traditional assessment of soil erodibility is no longer sufficient. The influence of (clay) mineralogy and suction also plays a significant role in this regard. Currently, we are developing a new rotary erosion device for this research, which will enable us to not only accurately capture the erosion process, but also monitor the development of suction during this process.

Land subsidence

Land subsidence, especially in peat meadow, attributes to the greenhouse gas emissions of the Netherlands. The research in our lab focusses on the long-term settlement of peat due to physical processes like creep. In the NOBV research, we quantify the greenhouse gas emissions from peat meadow lands.

Another subject related to land subsidence is the shrink/swell behaviour of clay. Due to climate change, both extremely dry and extremely wet conditions are becoming increasingly more common, leading to increasing fluctuating groundwater levels and therefore suction stress levels. This, in combination with (clay) mineralogy, can cause swelling and shrinking of the soil. Subsequently, this can lead to significant damage to buildings and infrastructure.